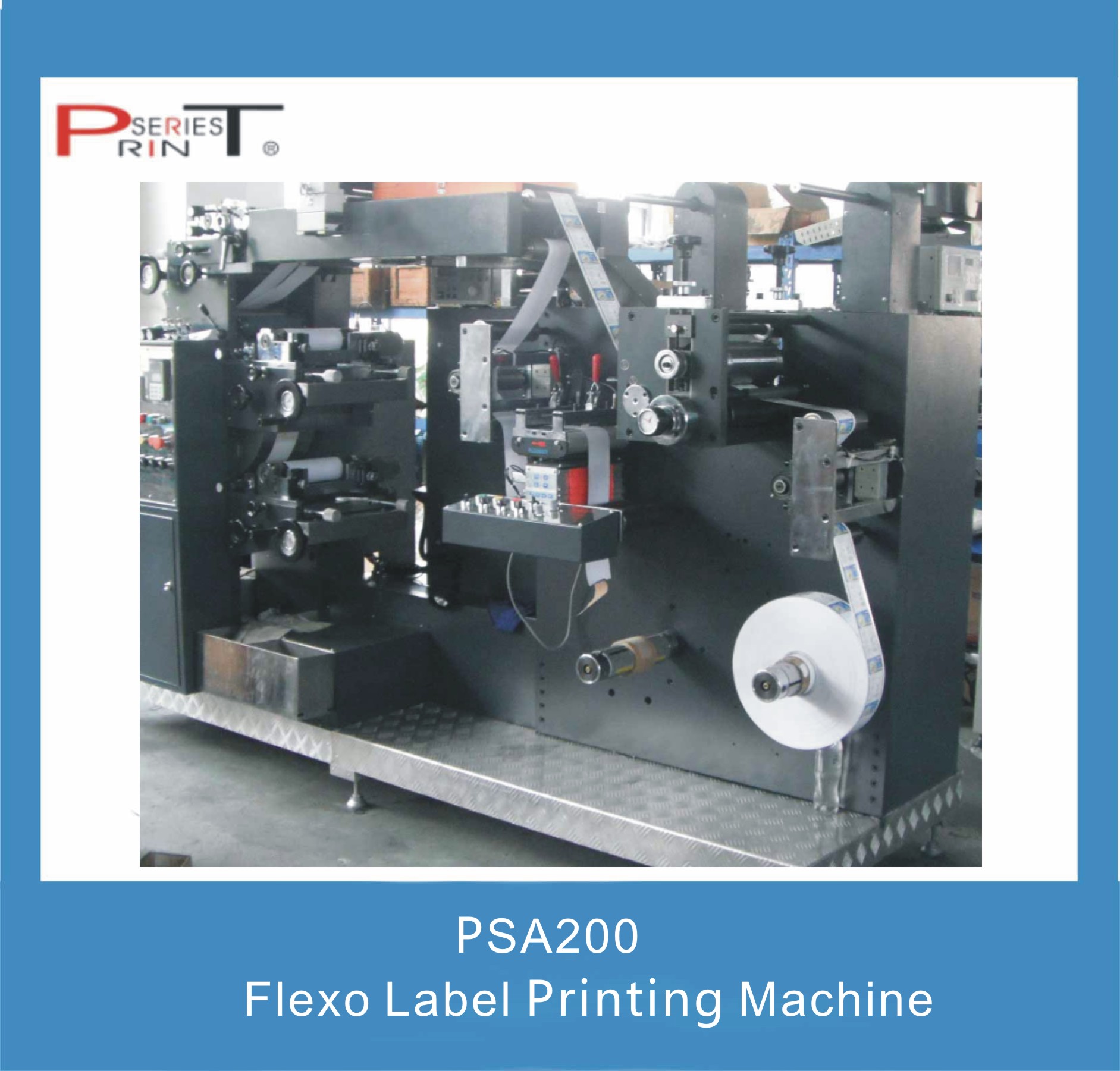

Adhesive Printing Machine

Applications and Optional Device of Waterbase Ink Printing Machine

1. Printing Material: thickness around 75~ 250g/㎡

2. Corona Treatment: Optional for plastic materials like Bopp, PVC, PET and etc.

3. Stroboscope Image: Installed on machine for counting numbers of printed labels electronically and monitoring each labels quality.

Features

1. UV or IR device for optional.

2. Rotary die cutting unit, lamination device, winder and rewinder device, auto discharge.

3. Feeder and rewinder paper with Tension control system.

4. High quality ceramic anilox with 800DPI or 400DPI for optional basing on customer own needs.

5. Standard offering 3 sets printing cylinder and gears.

6. Die cutting device with magnetic cylinder 1 set.

7. Fuji Frequency made in Japan; Mitsubishi tension controller made in Japan, Ceramic anilox adopt Germany Technical, UK UV lamps.

8. Resin plate or laser plate, but recommend flexo plate which is environmental especially suitable for food and medicne label printing industry.

9. Flexible changing cylinder size, high speed at 60 meters/ min.

Specification

| Max. Material Width | 210mm |

| Max. Printing Width | 200mm |

| Max. Printing Length | 340mm |

| Min. Printing Length | 170mm |

| Max. Printing Speed | 60m/min |

| Analog Cylinder | 400lpi/800lpi per spare inch(laminating) |

| Voltage/ Power | 380V/8.4KW(Include 3KW UV) |

| Weight | 3T |

| Size | 2800*1100*2000mm |