All Products

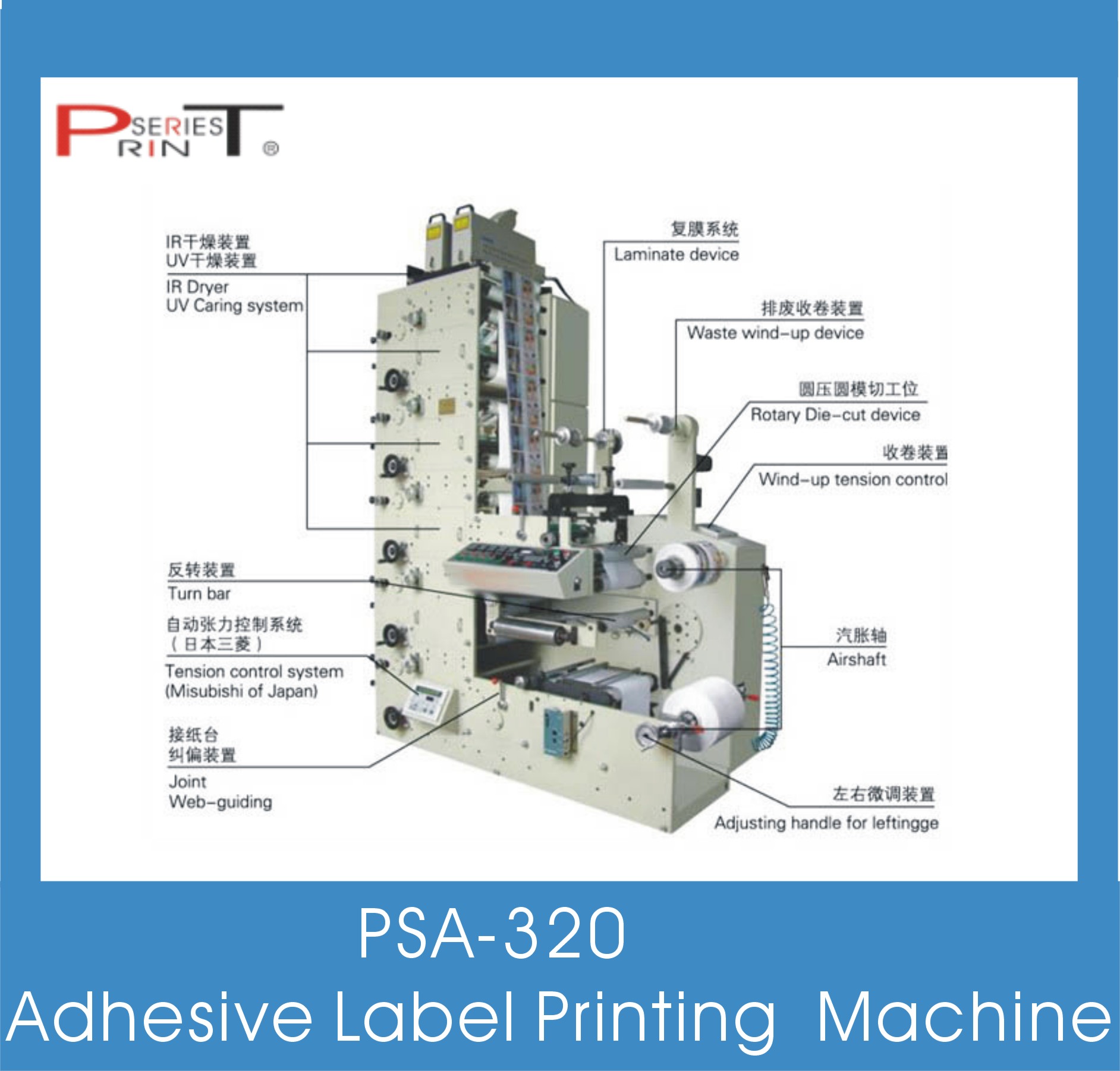

Features of Flexographic Printing Equipment PSA320

1. Ceramic Anolox Cylinder for ink transfering system.

2. 360 degree plate-adjustment for each print unit.

3. IR or UV dryer for optional basing on different printing materials.

4. Wind and Rewind device are controlled by magnetic power brake cluch , Mitsubishi Tension controller made in Japan.

5. Separated Printing rollers and ink rollers for keep running when machine stops.

6. Die cutting unit for label die cutting after printing, all process finish on one line.

7. Main motor adopts frequency conversion for controlling speed.

8. It is roll to roll type printing machine with print, light, drying, laminating, die cutting, rewinding all finished in one process.

9. Especially when printing trade invoice and top grade adhesive labels, this machine will be the ideal choice.

Specification

| Printing Speed(Max) | 50m/min |

| Printing Color | 5colors |

| Max Width Paper | 320mm |

| Max Printing Width | 310mm |

| Max Unwinding Diameter | 600mm |

| Max Rewinding Diameter | 600mm |

| Printing Length | 175-320mm |

| Precision of Chromatography | +/_0.1mm |

| Dimensions | 2*1.1*2.6M |

| Machine Weight | 2T |